High-Precision Displacement Sensors for Vibration Monitoring

Reliable eddy current and capacitive displacement sensor systems for condition monitoring and predictive maintenance

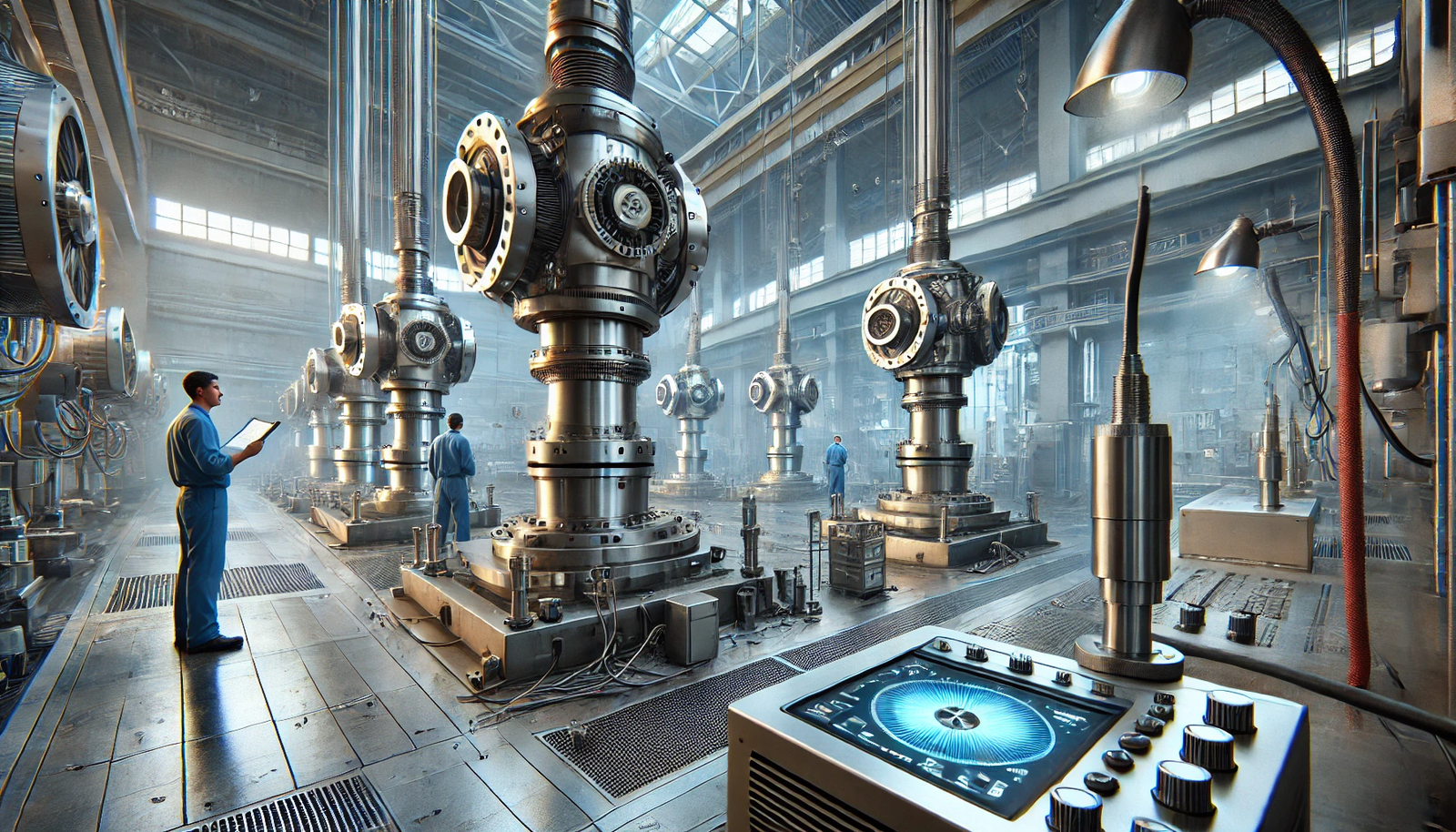

Displacement Sensors (Capacitive or Eddy Current) for Industrial Monitoring

Accurate displacement measurement is essential in vibration analysis, especially in detecting small changes in shaft movement, rotor dynamics, or bearing wear. Displacement sensors—particularly capacitive and eddy current types—are widely used in industries where non-contact, high-resolution measurement is critical. These sensors detect changes in distance between the sensor and a target surface, converting physical movement into reliable electrical signals for detailed analysis.

Noise Vibration Monitoring, a leading B2B provider in North America, delivers best-in-class displacement sensor technologies designed for reliability, precision, and durability. Our team has rapidly grown into a trusted source for industrial sensing solutions, offering customers tailored systems, real-time monitoring tools, and scalable integrations. With a commitment to quality, innovation, and support, we help clients unlock the power of accurate monitoring to reduce failures and maximize uptime.

1. Hardware Components

- Capacitive displacement sensors with sub-micron resolution

Proximity & Presence Sensors – deliver high-precision distance measurement for position feedback in sensitive equipment. - Eddy current sensors with rugged, non-contact operation

- Chemical and Gas Sensors – repurposed for harsh environments where corrosion, temperature, or contamination resistance is key.

- Precision analog-to-digital converters (ADCs) for high-speed sampling

SFP Transceivers – support fast, noise-free signal transmission between sensor systems and data processors. - Shielded cables and low-noise connectors for interference reduction

Ethernet Media Converters – enable clean, stable signal transfer over long distances in industrial conditions. - Compact sensor modules with integrated mounting brackets

Zigbee End Devices – support modular design and wireless flexibility for embedded displacement sensing applications.

2. Software Capabilities

- Intuitive user dashboards for real-time displacement tracking

- Digital filtering and calibration tools

- Custom threshold settings with automatic alarms

- Data export formats for waveform, trend, and historical logs

- API support for ERP/SCADA system integration

3. Cloud Integration & Remote Monitoring

- Scalable cloud dashboards for global sensor data access

- Multi-device sync for plant-wide monitoring

- Real-time alerting with SMS/email/push options

- Historical data visualization with trend forecasting

- Integration with Industry 4.0 platforms and IoT middleware

Core Components of Displacement Sensor Systems

In addition to offering products and systems developed by our team and trusted partners for displacement sensors (capacitive or eddy current), we are proud to carry top-tier technologies from Global Advanced Operations Tek Inc. (GAO Tek Inc.) and Global Advanced Operations RFID Inc. (GAO RFID Inc.). These reliable, high-quality products and systems enhance our ability to deliver comprehensive technologies, integrations, and services you can trust. Where relevant, we have provided direct links to select products and systems from GAO Tek Inc. and GAO RFID Inc.

Key Features and Functionalities

- Micron-level accuracy and stable output over wide temperature ranges

- Wide frequency and displacement measurement range

- Non-contact sensing reduces mechanical wear

- Compact and low-maintenance design

- Fast response time for high-speed applications

Integrations and Compatibility

- Supports Modbus, OPC UA, and analog/digital outputs

- Seamlessly integrates with PLCs, DCS, SCADA, and BMS platforms

- Compatible with edge computing devices and IoT gateways

- Designed for integration into existing predictive maintenance workflows

Benefits of Our Displacement Sensor Solutions

- Early detection of shaft misalignment, rotor imbalance, or bearing wear

- Enables proactive maintenance and reduced unplanned downtime

- Accurate data for performance benchmarking and compliance

- Scalable for OEMs, multi-site manufacturers, and critical infrastructure

- Backed by expert support, training, and system customization

Applications

Turbine shaft displacement monitoring

Motor and gearbox misalignment detection

Aerospace engine component tracking

Semiconductor and nanotech equipment calibration

Paper mills, steel plants, and process automation systems

Industries We Serve

Power Generation and Utilities

Aerospace and Defense

Heavy Equipment Manufacturing

Semiconductor and Electronics

Automotive and Transportation

Relevant U.S. & Canadian Standards (Abbreviated List)

- ISO 7919

- ISO 10816

- IEEE 1434

- CSA C22.2

- ANSI/ISA-75.05.01

Relevant Industry Standards and Regulations (U.S. & Canada)

- ISO 7919

- ISO 10816

- IEEE 1434

- CSA C22.2

- ANSI/ISA-75.05.01

Case Studies

(U.S.): Gas Turbine Shaft Monitoring

A power generation firm in Georgia used our eddy current displacement sensors to monitor shaft vibration in gas turbines. The data revealed a misalignment issue that was corrected before major damage occurred, saving over $500,000 in potential downtime and equipment repairs.

(U.S.): Aerospace Engine Validation

A U.S.-based aerospace R&D center integrated our capacitive displacement sensors into their turbine test stands to measure axial rotor shifts. Our systems enabled accurate readings during thermal cycling tests, contributing to FAA certification and speeding up time-to-market.

(Canada): Steel Mill Motor Diagnostics

A steel manufacturer in Ontario deployed our displacement sensors to monitor heavy-duty motor positioning and vibration. The solution helped reduce mechanical failures and unplanned downtime by 30%, improving plant efficiency and safety.

Looking for expert guidance or tailored displacement sensor solutions?

Contact Noise Vibration Monitoring for product support, technical specifications, or custom system design. Our team is here to help you find the right solution for your monitoring needs.